Making Firing Pin Stop Screws

My Winchester Model 06 22 pump had been missing one of the two small screws in the top of

the breech bolt as long as I can remember. I removed the one remaining screw and attempted to determine what size it was.

The diameter was somewhere between a number two and a number three machine screw and I didn't have a thread gauge

that could fit the very fine threads. After some searching on line I found a post on the RimfireCentral.com that the screws

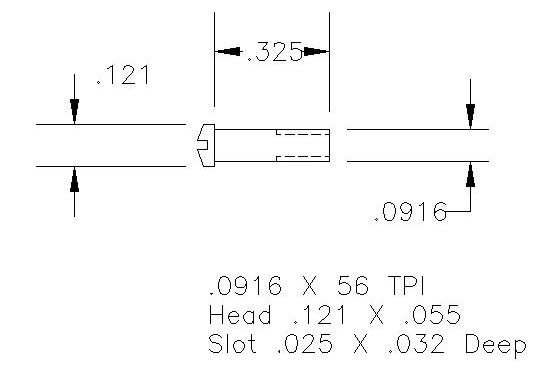

were called "Firing Pin Stop Screws" and were a special diameter of .0916 with 56 threads per inch.

Here is a drawing of the screw:

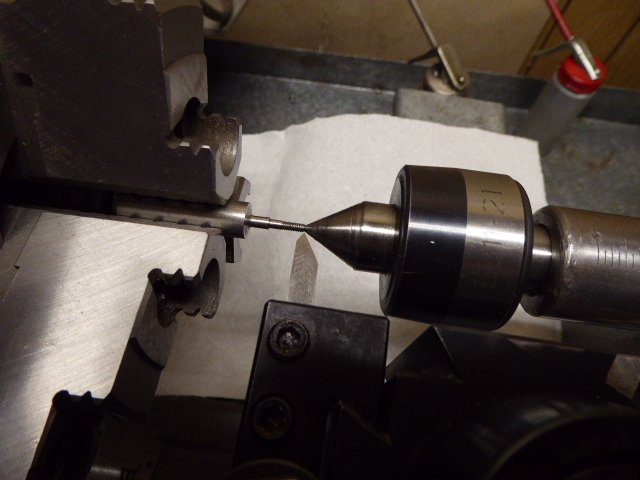

Now to make a pair of new screws I experimented with different pieces of steel and found that some stainless

I had machined the best. The fine threads required a very sharp cutting tool and the hole for the tailstock center was made with

the smallest center drill I had, marked #1; and I only drilled to the start of the 60 degree taper.

I had previously removed the breech bolt so I was able to thread it onto the screw while it was still

chucked up to check the threads for fit. That way I could take additional threading cuts if needed without disturbing the

threading set up. After the threads were done I cut the screw from the piece and then used a simple collet to hold the threaded

end as the lathe chuck couldn't close down small enough. I finished the head of the screw and used the cross feed to cut the slot

in the head.

Here is the original screw on the left and one of the new ones on the right.

Here is one of the new screws test fitted in the breech bolt.

Back to Index

Created on ... November 23, 2016